Custom graphic overlays are essential for enhancing not only the usability but also the aesthetics and professionalism of projects, such as control panels, electronics, keyboards, and DIY devices. Moreover, they serve as a functional interface between users and the device, while simultaneously protecting the underlying components. In this guide, we will answer the key questions about creating effective custom graphic overlays, providing detailed explanations and practical tips.

What Are Custom Graphic Overlays and Why Are They Important?

Definition and Purpose

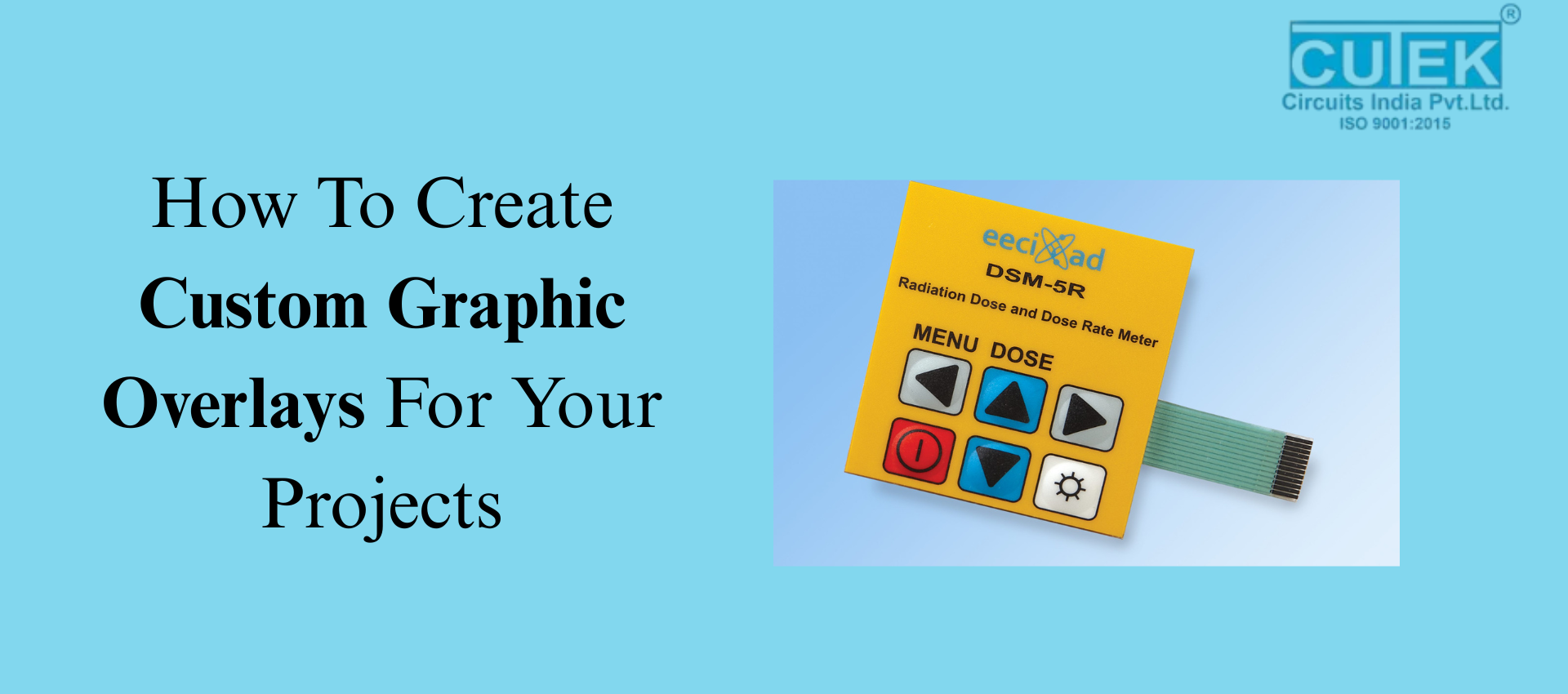

Custom graphic overlays are the topmost layer on devices or panels that display buttons, labels, and icons. They guide user interaction while protecting the electronics underneath.

Benefits of Custom Graphic Overlays

- Firstly, durability: protects buttons, switches, and panels from wear.

- Secondly, enhanced usability: clear labeling and icons make devices intuitive.

- Thirdly, aesthetic appeal: gives a professional, polished look.

- Finally, customization: allows tailored designs for specific project requirements.

Materials Commonly Used

- Plastic: PVC, polycarbonate, acrylic – lightweight and easy to print.

- Metal: Aluminum – durable for industrial applications.

- Vinyl: Often used for decorative or temporary overlays.

Applications

-

Control panels, electronic devices, keyboards, machinery interfaces, DIY electronics, home automation systems.

How Do I Create a Custom Graphic Overlay for My Project?

Step 1 – Plan Your Design

- First, identify project requirements, including size, button layout, and display elements.

- Next, decide on legends, text labels, and icons.

- Finally, use recommended tools such as Adobe Illustrator, CorelDRAW, or other vector-based software.

Step 2 – Choose the Right Material

- Options: PVC, polycarbonate, acrylic, aluminum.

- Consider flexibility, durability, transparency, and environmental resistance.

Step 3 – Create the Design File

- Use vector graphics for scalability and precision.

- Include dimensions, cut-outs, legends, icons, and color separations.

- Ensure high resolution and sufficient contrast for readability.

Step 4 – Printing or Engraving

- Printing: Screen printing, UV printing, or digital printing.

- Engraving: Laser or mechanical engraving for durability.

- Protective coatings can enhance longevity and scratch resistance.

Step 5 – Finishing and Application

- Add laminates or protective layers if needed.

- Apply adhesive backing for easy installation.

- Carefully align and attach to the device or panel.

Best Practices and Common Mistakes

Best Practices

- First, keep text legible and icons clear for usability.

- Next, use contrasting colors to ensure better visibility.

- Then, test the overlay on a prototype before final production.

- Finally, consider environmental factors such as heat, moisture, and chemicals.

Common Mistakes to Avoid

- Firstly, avoid using low-resolution graphics.

- Secondly, ensure correct dimensions and properly aligned cut-outs.

- Thirdly, do not overcrowd the overlay, as it reduces clarity.

- Finally, avoid using incompatible materials that may warp or degrade.

Creating a custom graphic overlay therefore requires careful planning, precise design, and proper material selection. Furthermore, by following best practices and avoiding common mistakes, you can produce overlays that are not only functional but also durable and visually appealing. Additionally, properly crafted overlays enhance the usability and professional appearance of your projects, while simultaneously protecting the underlying components.

Contact Cutek Circuits

📞 Phone: +91 92255 24304 | +91 98237 84304 | +91 87930 34304

📧 Email: info@cutekcircuits.com | sales@cutekcircuits.com

🌐 Website: https://cutekcircuits.com